This year, Lencolo presents the theme “New Factory, New Materials, New Journey.” It reflects not only our strategic direction, but also our continuous evolution.

From our early beginnings as a small chemical company, to becoming Guangdong Lencolo New Material, and now advancing toward our new large-scale manufacturing base in Nanxiong, Lencolo has grown through determination, professionalism, and dedication to innovation.

Like many emerging technology companies, we encountered misunderstandings and doubts in our early years. Some questioned our capabilities; others underestimated our technical strength. But our customers are wise — and the market always speaks the truth. Through consistent effort, solid performance, and real results, Lencolo has proven its value.

Today, we stand firm on the foundation built by our team and our partners.

Tomorrow, we will become even stronger.

Lencolo now operates a 3,000 m² R&D and engineering laboratory in Dongguan and is building a new M3-grade production plant on nearly 100 acres of land in Nanxiong. When the new facility is fully completed, we warmly welcome all our global partners and customers to visit and see our progress firsthand.

Together, we look forward to shaping the future of UV-curing materials.

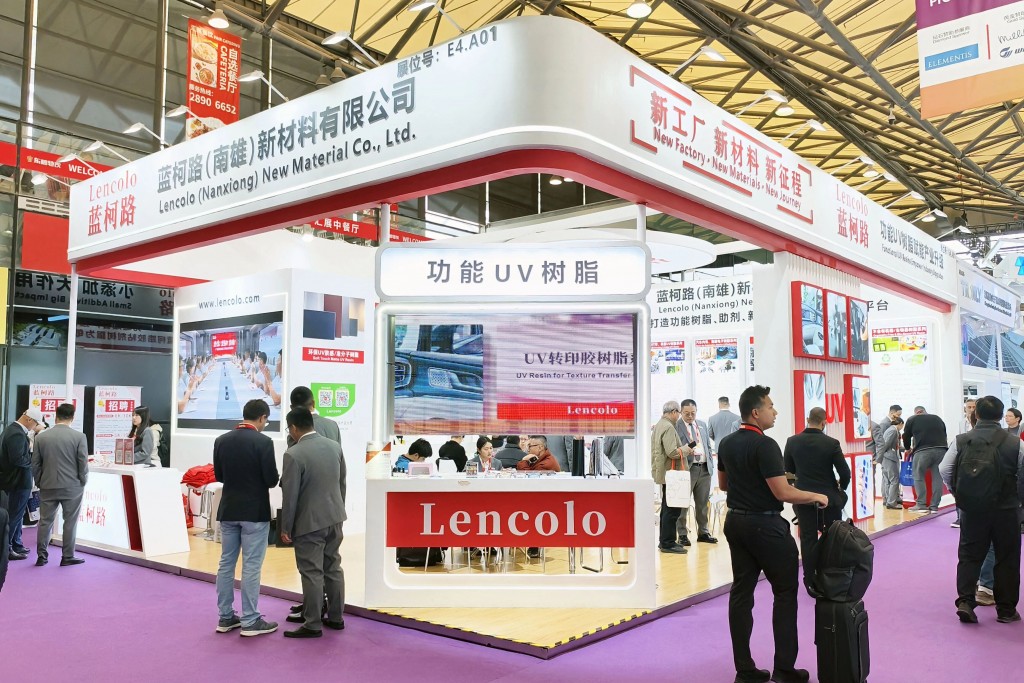

On November 27, the three-day 2025 Shanghai International Coatings Expo successfully concluded at the Shanghai New International Expo Centre. As a UV-curable raw material supplier focused on coatings, inks, adhesives and related fields, Lencolo showcased its core theme of “New Factory, New Materials, New Journey.”

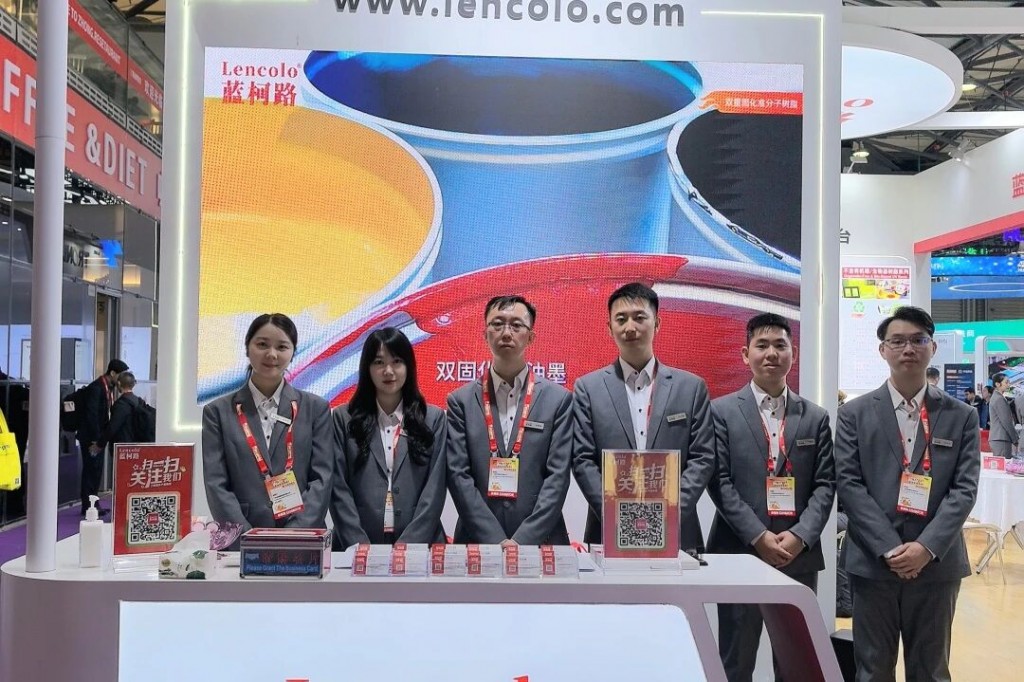

At the brand’s signature red booth E4.A01, Lencolo’s team of more than 30 professionals delivered warm and dedicated service, demonstrating to global customers the company’s innovative capabilities and strong supply assurance across its UV-curable resins, monomers, and additives.

At this year’s exhibition, our soon-to-be-launched raw materials manufacturing base became a major focus among customers. Dedicated to UV-curable products, the new facility adopts automated batching and continuous reaction processes, doubling UV resin production capacity and achieving a purity control accuracy of 99.8%.

Equipped with a full-process environmental treatment system that enables zero wastewater discharge, the plant not only meets downstream coatings, inks, and adhesives manufacturers’ needs for large-volume and highly stable supply, but also provides strong raw material support for their environmental compliance.

Focusing on the core demands of UV functional new materials, we showcased our full range of flagship products, covering multiple application fields across coatings, inks, and adhesives.

At this new stage of development, our factory will fully leverage the advantages of its independent synthesis and production qualifications, actively aligning with national policy directions and formulating a series of forward-looking new initiatives.

In innovation and R&D, we will increase investment in research, deepen industry–academia–research collaboration with institutes and universities, and further enhance the technological value and market competitiveness of our products.

In talent development and recruitment, we will establish a dedicated talent development fund and introduce attractive talent policies to bring in top industry professionals, strengthening both our technical and management teams.

In market expansion, Lencolo will continue to actively explore domestic and international markets, participate in global industry exhibitions, and further enhance brand visibility. We will also deepen strategic cooperation with major enterprises to build a stable and long-term customer network.

Tech-Inspired Transparent Display:

The transparent digital screen at the center of the booth allowed visitors to clearly view our company’s development journey and product applications at a glance.

Thoughtful Tea & Coffee Area:

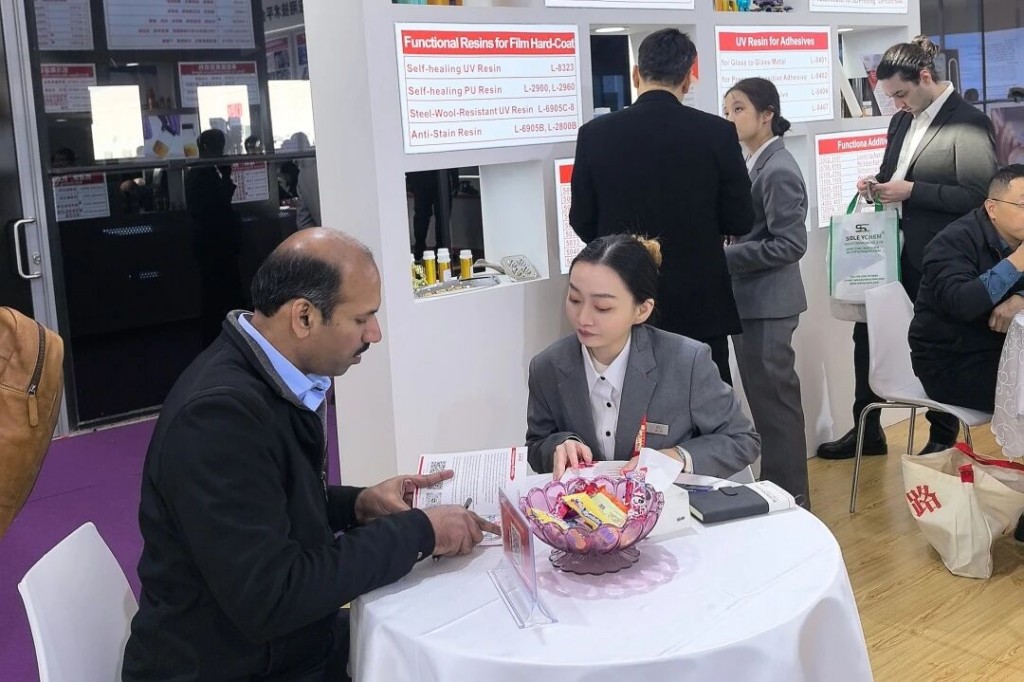

The booth's coffee and refreshment area became a “buffer space” for in-depth exchanges between clients and our technical team. Over the three days, it welcomed more than 800 visitors, with many customers finalizing testing directions on-site, followed by continued support from our offline business team.

Signature Red Branding:

For many years, Lencolo has maintained its iconic red booth design, making it highly recognizable among numerous exhibitors. It has become a clear landmark for customers in the coatings, inks, and adhesives sector seeking raw material suppliers.

Dressed uniformly in deep gray suits, Lencolo’s 34-member team demonstrated clear division of roles and highly efficient collaboration. The Technical Advisory Group addressed over 150 professional questions on-site, including topics such as the application directions of functional UV resins and examples of functional additive usage. The Business Liaison Group quickly responded to customer requests for samples and production timelines, issuing nearly 200 samples within three days and confirming 38 new potential collaborations. The Logistics & Coordination Group ensured smooth booth operations, presenting a professional image that earned client recognition. Multiple new and existing customers remarked: “Your team’s service alone reflects the rigor and professionalism you uphold in raw material quality.”

Keep the Collaboration Going Online!

For customers unable to visit Booth E4.A01, scan the QR code below to access:

Although the 2025 Shanghai Coatings Expo has concluded, our “New Journey” has only just begun. Looking ahead, we will leverage our new factory as a production backbone and new materials as a technological core, continuously providing high-quality UV-curable raw materials and services to customers in coatings, inks, and adhesives. We look forward to working hand in hand with you for mutual success!

#Lencolo #CHINACOAT #CHINACOAT2025 #CoatingShow #UVResin #UVCoating #UVInks #UVMaterials #Shanghai

2022-08-03

2025-01-06