When people hear about UV (ultraviolet) and EB (electron beam) curing, the first reaction is often concern:“Those sound like high-energy technologies—are they safe?”It's an understandable question. UV light can cause sunburn, and “electron beam” sounds like radiation.But in reality, UV/EB curing has been safely used in industry for decades, supported by scientific research, engineering standards, and extensive field experience.

At first glance, ultraviolet energy seems intense. After all, it's the same type of light that causes sunburn.

But in UV curing systems, this energy is carefully controlled and precisely targeted to trigger polymerization—transforming liquid coatings, inks, or adhesives into durable solid films within seconds.

Ultraviolet light, part of natural sunlight, is divided into UVA, UVB, and UVC ranges.

Industrial UV curing systems use mercury lamps, metal halide lamps, or modern UV LED lamps to produce specific wavelengths that initiate curing.

Possible risks include direct exposure, which can irritate eyes or skin, and ozone formation from older UVC lamps, which can affect air quality.

Fortunately, modern systems are designed to eliminate these risks. They operate in enclosed chambers or use shielding and filtered glass to block harmful wavelengths.

UV LED curing, emitting primarily long-wave UVA, produces no ozone and offers superior safety and efficiency.

With basic protective gear and standard operating procedures, UV curing is entirely safe and highly reliable in industrial environments.

“Electron beam” may sound intimidating, but the technology behind EB curing is far from dangerous.

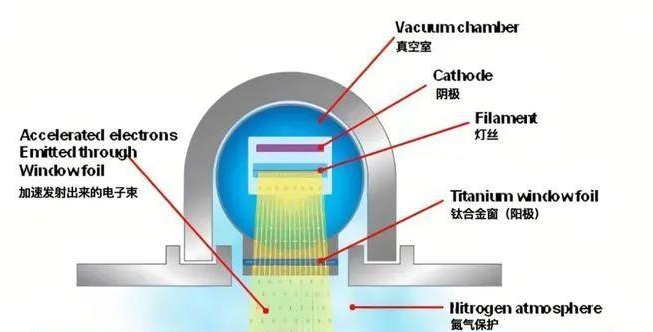

Rather than radioactive radiation, it uses accelerated electrons—pure electrical energy—to initiate crosslinking directly in the coating material.

EB curing delivers instant results without heat, solvents, or photoinitiators. It’s fast, energy-efficient, and produces minimal waste.

While direct exposure to the beam can be harmful and a small amount of X-rays may be produced during operation, both risks are completely contained through equipment design.

Industrial EB systems are built with thick steel or lead-lined enclosures and automatic safety interlocks.

If the chamber is opened, the beam shuts off immediately. Once powered down, no residual radiation remains.

In short, EB curing is an electrical process, not a nuclear one—high in power, low in risk, and proven in performance.

The safety of UV/EB curing is not theoretical—it’s been proven through decades of industrial practice.

Both technologies rely on controlled energy, not radioactive sources, and their potential hazards are limited to direct exposure under abnormal conditions.

Today, UV/EB curing is widely used in industries where precision and safety are paramount, such as printing and packaging, wood coatings and furniture finishing, electronics and semiconductors, medical devices, and food or pharmaceutical packaging.

These are among the most tightly regulated sectors in manufacturing, and the continued use of UV/EB curing in these areas clearly demonstrates its reliability and safety.

Every form of energy requires respect—and control.

The same principle applies to UV and EB curing: while both involve high-energy processes, they are designed, engineered, and operated to be safe.

Just like natural gas in a kitchen stove—powerful yet safe when used correctly—UV/EB curing delivers clean, fast, and efficient performance under controlled conditions.

With proper equipment design, shielding, and training, it remains one of the most advanced and sustainable technologies in modern manufacturing.

#UVCuring #EBCuring #IndustrialSafety #CleanTechnology #SustainableManufacturing #AdvancedCoatings #EnergyEfficiency #RadiationSafety #SmartProduction #EcoInnovation #GreenIndustry

2022-08-03

2025-01-06