In the world of industrial coatings, curing is more than just a step in the process — it defines the final performance of the product. Whether you're coating plastic, metal, wood, or composite materials, the curing method you choose can impact everything from durability to production speed. In recent years, dual-cure coating systems have started to gain traction, but how do they actually compare with conventional single-cure systems?

Let's take a closer look at how they differ — and where each one makes sense.

Single-cure coatings rely on one type of curing mechanism, typically UV light, heat, or moisture. They're straightforward, often fast, and easy to run in a controlled environment. However, their effectiveness can be limited by the shape of the part or the material being coated.

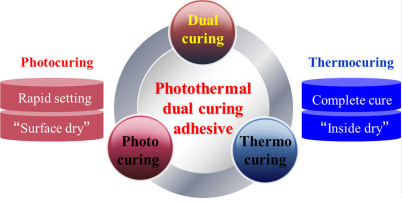

Dual-cure coatings, on the other hand, combine two different curing mechanisms — most commonly UV + thermal, or UV + moisture. This hybrid approach allows the coating to cure instantly on the surface (thanks to UV), while the second mechanism continues curing deep inside the film, even in shaded areas. It’s a more robust and versatile solution, especially for complex or sensitive applications.

One of the common issues with single-cure UV systems is poor adhesion on difficult substrates such as plastics, glass, or low-energy materials. Since UV curing is a surface-driven reaction, the result can be a hard but brittle layer that doesn’t always bond well.

Dual-cure coatings overcome this by enabling secondary chemical crosslinking, which takes place beneath the surface. This deeper reaction greatly improves adhesion, especially on materials where surface preparation is limited. For manufacturers working with a wide range of substrates or non-uniform shapes, this can be a game-changer.

In terms of performance, single-cure coatings are often sufficient when the substrate is flat, exposure is even, and environmental demands are moderate. They're fast and efficient — but may fall short in durability, especially under mechanical stress or chemical exposure.

Dual-cure systems offer a more balanced set of properties. The dual-phase curing leads to a stronger, more resilient coating that holds up better against abrasion, heat, moisture, and chemicals. And because the second cure phase can proceed independently of light, it ensures complete crosslinking even in complex geometries.

From a production perspective, single-cure systems are great for speed and simplicity. They work best when parts are uniform and curing conditions are tightly controlled.

But in many industries — such as automotive interiors, electronics housings, or wood furniture — parts often include curves, gaps, or shaded surfaces where UV light can’t fully reach. In these cases, dual-cure coatings provide greater process flexibility without compromising throughput. Surface curing can happen instantly, while the secondary cure continues as the part moves through the line.

Both systems are considered more environmentally friendly than traditional solvent-based coatings. They help reduce VOC emissions and energy consumption. However, dual-cure systems can offer additional advantages, such as lower cure temperatures, fewer emissions, and better compatibility with LED-UV equipment, making them a strong fit for companies seeking to align with sustainable manufacturing goals.

If your product involves complex shapes, difficult substrates, or high-performance requirements, a dual-cure coating will likely give you better results. It offers the speed of UV curing and the depth of chemical or thermal crosslinking — ensuring reliable performance even under demanding conditions.

On the other hand, if your process is optimized for flat, easy-to-coat parts, and you prioritize simplicity and speed, then a single-cure system may be more than adequate.

The best choice depends not only on what you're coating, but also on how you're producing it, and what your customers expect from the final finish.

As product designs become more intricate and expectations around coating performance grow, dual-cure technology is likely to play an increasingly important role. It’s not just about curing faster — it’s about curing smarter.

If you're exploring better options for your coating line, or considering a move toward dual-cure systems, our team is here to help. We work closely with manufacturers to tailor resin and formulation systems that match both technical needs and production realities.

Let's talk about how we can improve your coating performance — from the surface to the core.

#DualCureCoating #UVCoating #HighAdhesion #CompleteCuring #LowVOC #AutomotiveInteriors

#ElectronicsFinishing #WoodFinishing #GreenManufacturing #IndustrialCoatings

2022-08-03

2025-01-06