Application: UV adhesive, UV-3D printing, UV nail polish, UV ink, UV coating, UV conversion, adhesive transfer, UV pressure sensitive adhesive, etc.

Contact UsDescription

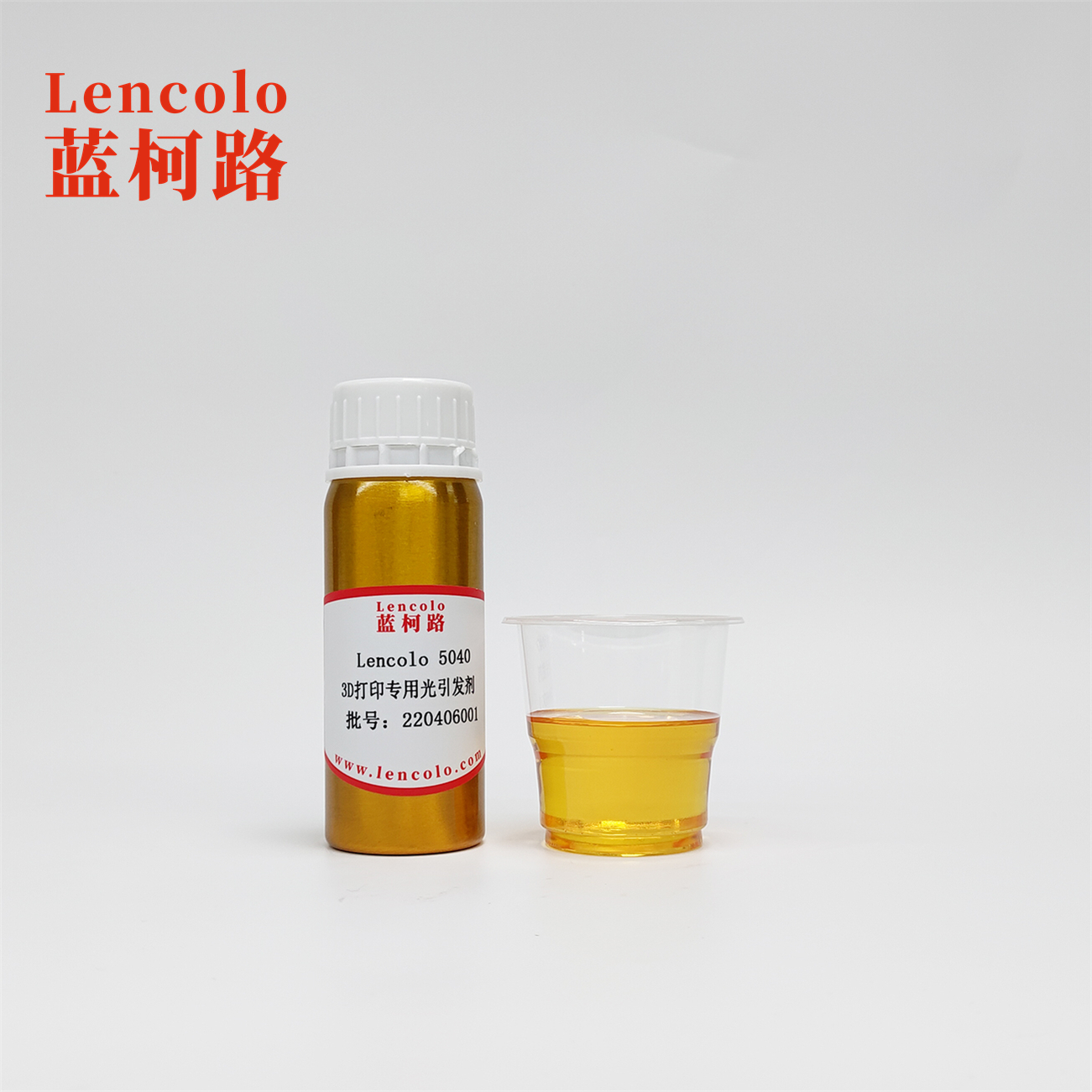

Product: Photoinitiator for 3D printing

Lencolo 5040 has a strong absorption peak, and the effective absorption peak is as high as 400~450nm, the excited free radical state is more active after being illuminated, thus triggering a higher polymerization ability strong, dedicated to various unsaturated UV polymerization of the system.

Chemical & physical data

| Appearance | Transparent light yellow liquid |

|---|---|

| Purity (%) | ≥98 |

| Density (g/cm³, 25ºC) | 1.1±0.1 |

| Volatile content(%) | ≤0.5 |

| Ash content(%) | ≤0.1 |

| Absorption peak(nm) | 265-450 |

Performance

1. Especially suitable for UV 3D printing field, it has better curing effect than TPO, under equal added amount, the finished product printed out has better details than TPO. at TPO's

The same effect can be achieved with 60% addition

2. Impurity-free transparent liquid, it is more convenient to add various UV systems

3. Higher absorption peak, applied to color, dark, black UV body deep curing, bottom solidification is more thorough

Application

UV adhesive, UV-3D printing, UV nail polish, UV ink, UV coating, UV conversion, adhesive transfer, UV pressure sensitive adhesive, etc.

Storage, shelf time and Packing

To prevent the product from polymerization and gelling, please keep it sealed and away from heat and light. Recommended storage temperature is not higher than 30°C. Unused products must be sealed and stored in a timely manner and cannot be stored in the open. Safe storage time is 6 months at room temperature( 25ºC) and under ventilation. 25KG/barrel

Tips: Lencolo 5040 liquid photoinitiator, especially suitable for UV 3D printing field, more effective than TPOBetter curing, prints with finer detail than with TPO.

Note: Technical data represents typical values only. In view of the differences in formulas, production process, conditions, all the above statements must be adjusted according to the actual situation, our company does not make any promises. Our company reserves the right to reform its products without prior notice of any changes.